Every once in a while I’d have an issue with my Pfaff 1222E. It usually happened when I was sewing curtains. Heavier fabric, long straight seams, pressing on the control pedal consistently for 10 foot hems. When I took my foot off the pedal the machine would keep sewing! Even more distressing, it would speed up like a little German devil. The only way to stop the madness was to hit the power button.

I’m not the only one who occasionally got a runaway sewing machine. It’s scary, and seemed like an expensive fix. The foot pedal and power outlet are on the same plug, and this part costs $80+ on Ebay! But my wiring was fine, it was just the pedal that was going nuts.

I tried to repair the pedal, but when I opened it up a tiny little resistor cracked and fell off. I confirmed with my electrical-genius friend that this was probably the problem, but we couldn’t really think of an easy way to fix this. The solution seemed to be replacement! (Another solution can be to clean lint out of the pedal, but that wasn’t my problem this time).

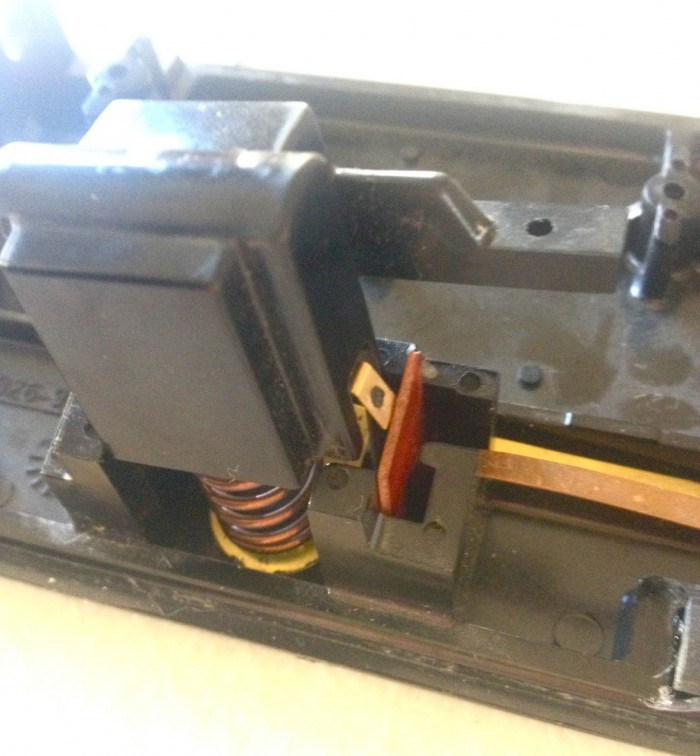

Inside the pedal

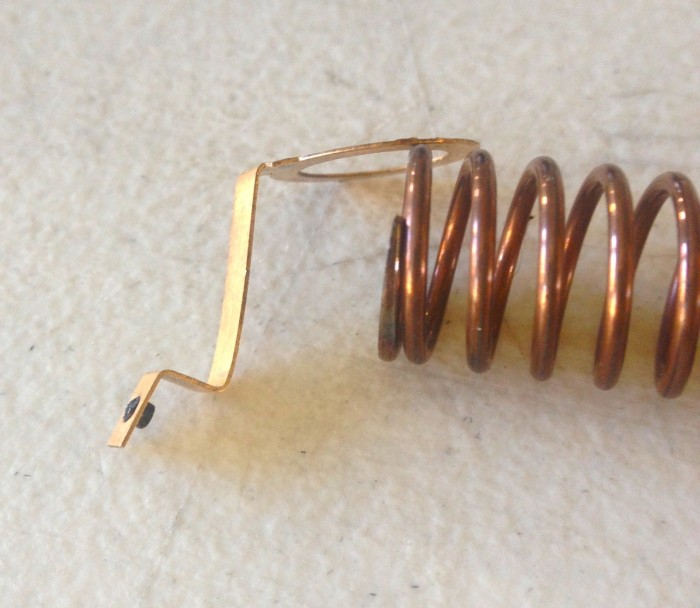

When you press on the pedal, this spring is what’s moving.

There should be a tiny black bump on the left of the gold piece…

I tried to find the same Pfaff pedal ($80+ online), or at least a white one, but in the end I bought a Singer from the 80s for $15 and just cut off the pedal. Stripped the wires on the Singer and Pfaff pedals, and spliced them together. It works great now! Brian has created a video documenting his process, but it really is as easy as that!

Next time we have the soldering iron out I’ll do a proper join of the wires with heat shrink, but for now the electrical tape is working super fine.

A perk of this is that I cut the Pfaff wire near the pedal, and the Singer wire near the plug, so the resulting spliced wire is really long! This means I can run both wires behind my table and still pull the pedal out as far as I want.

If you have any questions about this machine, check out the comments on my earlier post. You can read tips and feedback from people who have used this machine for decades, from people who know a lot more about it than I do, and people who have just acquired one of these machines. And it’s the #2 Google hit when you search the Pfaff 1222e – amazing!