Tonight I will share an easy way to make tubing, which can then be used for button-loops, straps, or ties. I’d be interested in what else you could use this for. I’ve used this method on stretch and non-stretch fabrics, to make thin strips or round ropey tubes, from a few inches long to several feet. The way I used to do this was so difficult that I’ve avoided straps altogether, or top stitched bulky straps.

Fold your fabric in half lengthwise, right sides together. Your seam should be at least 1/4 inch away from the fold. If you want to make your strap wider, obviously increase the distance from the fold. If you want your strap to lay flat there should be a small seam allowance, but if you want round ropey straps be sure to have enough seam allowance to plump up the tube when you’re finished.

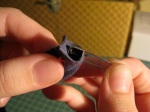

Attach a safety pin onto the end of the tubing, on the fold, going from the outside in.

Turn the safety pin so that the head is going into the tube of fabric.

Push the safety pin down the tube. The fabric at the beginning will bunch up as you push the safety pin deeper into the tube, so ease that with your fingers. You’re trying to turn that tube right-side out!

Keep pulling the pin down the tube, easing the bunching. Eventually the head of the pin will come out the far end of your fabric… Keep pulling it out until the entire piece is right-side out! Now you’ve got a nice tube, ready for anything.

In a couple days I’ll post the dress I made using this method. Until then, happy sewing!