For more information about the Pfaff 1222E, check out my initial review as well as my tips on threading with industrial cones. Also you can replace the pedal if you have a “runaway” vintage sewing machine.

As many of you know, especially if you follow me on Facebook, I love my Pfaff. Since I’ve been getting a fair amount of site visitors looking for information on the machine, I’ve decided to do an update, now that I’ve been using the machine for about 6 weeks. To recap (and get those search results, cha ching) it’s a 1982 Pfaff 1222E.

This post will probably not be too interesting to most readers, but hopefully I can share some insight with people thinking about getting one of these machines. From what I can tell, the normal price range is $300-400, depending on the machine’s condition and accessories.

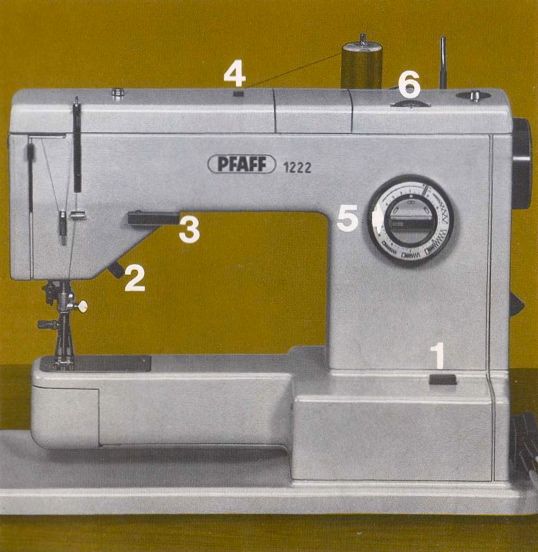

My machine came with a CD manual, which I’ve taken the instructional images from.

This is my first intentionally vintage machine. I learned to sew on a Singer that was probably made at the same time, but it didn’t seem vintage at the time. There have been plenty of older people (mostly women, although plenty of men have asked about that new sewing machine I constantly talk about on Facebook) who laugh at me when I tell them my vintage machine is from 1982, basically thinking I’m so young and naive to consider the early 80s vintage. If I were using a 30-year-old nail clipper, a tool that hasn’t really evolved much over its lifetime, I wouldn’t call it vintage. But a sewing machine that’s older than I am, in an industry that has seen lots of development and digital revolution, for which parts are no longer manufactured, in a throw-away culture? Yes, I consider that vintage, and if you think I’m naive for that then I think you’re outdated and delusional. So there.

I honestly haven’t used the table extension a single time. I do mostly apparel sewing, and the free arm actually works best for me. It’s smaller than on my last machine, and the perfect size for sleeves or legging hems, coming in at just over 9″. So while I’m definitely glad to have it, I’m glad I didn’t pay $50 for an acrylic table.

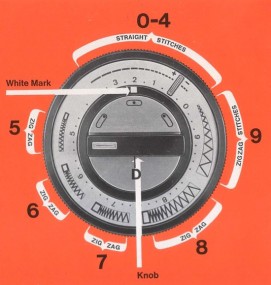

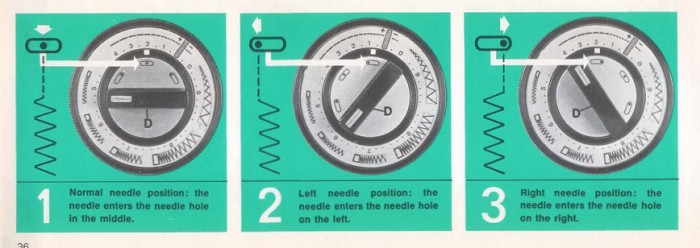

I’ve grown pretty fond of the setting dials. They are simple but very efficient! The outer ring adjusts stitch width and length, which makes sense if you look at the diagrams on it. The inner knob is for the needle position, which is essential in some of the decorative stitches, which are set through buttons on the top of the machine.

I’ve grown pretty fond of the setting dials. They are simple but very efficient! The outer ring adjusts stitch width and length, which makes sense if you look at the diagrams on it. The inner knob is for the needle position, which is essential in some of the decorative stitches, which are set through buttons on the top of the machine.

It took me a little while to figure out my favorite stitch settings, which I’ve marked with rhinestones. They’re removable if I ever change my preferences, and also delightful.

This dial also has a knob to adjust the needle position from left to right, which is essential for some of the decorative stitches.

Because you manually set the stitch settings (with dials), the machine doesn’t reset when you turn it off or move to a different stitch. This may be obvious, but it’s an extra step for those who are used to modern digitized machines.

One feature of the machine that may be worth noting is the automatic needle position: there is none. Whereas my last Singer would automatically pull the needle up to its highest position when I took my foot off the presser pedal (making it easy to pull the fabric out from the machine), and the industrial Juki I use at work puts the needle at its lowest position (so that I can pivot the fabric without losing my place), the Pfaff leaves the needle wherever in the stitch it is when I remove my foot. Despite the power and speed of the machine though, it’s pretty easy to take my foot off exactly where in the stitch I want the Pfaff to stop. I can stop the needle at its highest point to remove the fabric, or have it all the way down to hold the fabric in place. Of course I could always turn the wheel the reposition the needle, but who would want to do that?

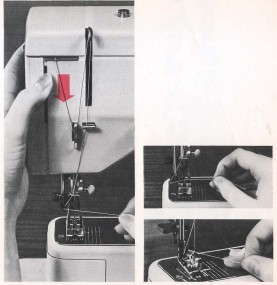

I have never been able to use an automatic threader on any machine I’ve ever used. I simply can’t understand them, and I have no problem threading a needle the old-fashioned way. Vintage all the way baby!

One neat little feature is this lever that can hook onto the presser foot. This takes the pressure off the foot, allowing you to match stripes and plaids easier. The Pfaff has a built-in walking foot! It’s called the Matchmaker foot. Occasionally fabric gets caught on the plastic piece, but it’s not really an issue. My biggest caution about the lever is to not leave it engaged all the time: because it reduces the pressure from the foot, the feed dogs don’t get a proper grip on the fabric, so stitches might come out wonky.

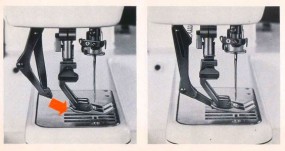

Which brings me to my biggest breakthrough: the Pfaff 1222E can use standard high-shank industrial feet. I absolutely hated the right-hole zipper foot that came with machine, and Pfaff-specific feet can get pretty pricey even without the widest selection. Meanwhile industrial feet are all over the place, and cost about $5-10 each. And they’re made for industrial use, so no worries about quality. The shape of the shank is a little different between the Pfaff and industrial feet, but the industrial shank fit on my machine perfectly (the third photo has a Pfaff foot on top and an industrial foot below; the important thing is that the knob fits into the same place). No other Pfaff site I saw had this insight, but I think the machine’s compatibility with less-expensive industrial feet is a huge bonus!

There is an adapter that lets you use snap-on feet on the Pfaff, but $70 for a foot?! That’s just nuts.

The slightly rounded plate under the free arm collects stray pins and loose threads from rolling around on my desk. I love this little tray!

If any of y’all have any questions about my Pfaff, let me know and I’ll try to answer.

For more information about the Pfaff 1222E, check out my initial review as well as my tips on threading with industrial cones. You can download the stitch pattern chart PDF here.

My family has had our 1222E since purchased by our grandmother in the 70’s. But I have a problem with it consistently seizing up. I take it to our local repair place here in Seattle, called Quality Sewing, and it lasts a little while, and then gets tight and seizes again. It’s seized right now. Any advice on either fixing the seizing, or recommending a skilled repair shop?

Did you find a solution? My machine is doing the same. I paid over $200 to fix it last year and now it’s even worse. Please follow up if you have any tips.

I wound up oiling the machine like crazy, which I know is bad, but better than throwing it away! It’s working great now. I also tightened the large screw head behind the bobbin casing which was buzzing and rattling. I somehow did this just by pressing on it with a finger while slowly running the machine. It was amazing how much that improved performance.

I hope I didn’t wreck it, but it already felt wrecked…

I have a collection of PFAFF 1222 ‘s as well as some 230 260 and 262’s I also have parts and lots of free advise… here comes some now!

The problem of seizing up is common in these 1222’s after long periods of storage. The other very common issue is the camstack cracking on these. This is an easy fix however make sure to check for any loose camstack parts before reassembly. Any loose parts, broken camstacks or even a broken needle in the hook assembly can make these seize up. After long periods of time old oil can build up in a thick and sticky goo and if oiled extensively will affect wiring, moving parts and even the motor. This goo can act as glue making parts move slowly and even leading to broken presser levers and reverse levers.

Conversely no oil over extended periods of time can cause some shaft points to begin to seize from lack of oil and reaction of bare metal to humid environments. So in short, there are a few things to check to determine which of these fits your scenario. The most common of these is just old sticky oil. It sounds from the initial post here that the machine was probably oiled to get the goo loosened up without actually proper disassembly and cleaning. This can lead to frequent seizing even after recent periods of use. If it’s bad enough you have to disassemble do yourself a huge favor and change out the motor brushes and clean the commutator and bearings while you’re in there!

Hi Bob, Are you interested in selling any of the Pfaff 1222 machines from your collection?

Bob any chance of changing the top brushes without taking out the motor, I can take out the bottom brushes.

I have the 1222E also. I bought it new in 1976. Quite fancy back then! My machine is currently sized up also. It sat a long time unused. I did some reading and found two possible causes.

1). The lubrication used originally is a “white grease” or lithium based lubricant. It can harden over time and cause slowing and sizing.

2) The camshaft may be cracked. I suspect this to be the case in my machine. It was working prior to my move. It may have been mishandled by my movers who did not see it as fragile.

I am taking it in to a Pfaff qualified repair center to get it repaired. I read about it first so I could fully communicate my thoughts and concerns to the shop.

When a machine sizes, there can be many hours to truly diagnose, obtain parts, and do repairs. Especially a machine as old as my girl! I don’t recommend trying to do repairs yourself unless it’s your livligood.

Good luck. I love my machine and feel it’s worth the cost of repair.

Jane, 200 is a little excessive unless you needed a lot of OEM parts. For that you should at least get a 1 year guarantee on work performed to ensure the correct diagnosis and repair was make initially. If you remove the top cover take a look at the camstack while rotating 1 revolution. If you find a crack in it this could also be binding. Take a close look at the counterweight as you turn by hand. If you see a small patch of dried up sticky oil your machine may just need a good cleaning.

No kidding $200 is excessive! The cam stack was replaced about 5 years ago by a guy in Utah. About two years later it started seizing up so I took it to a different repairman (I had since moved) and they told me that it needed a deep cleaning which would be $180. I gritted my teeth and paid it. I dug up the receipt and this was a year and a half ago. The machine was pretty idle for about 6 months and when I wrote my first comment it was way worse than before. Since it’s been more than a year, and I don’t trust that repairman, I’m not taking it back.

I guarantee there are no tangled threads, no broken needles, no cracked cam stack. I tightened the piece behind the bobbin casing and oiled most of the moving parts and it’s working great now. I don’t have the knowledge to take it entirely apart and I don’t think I have a trustworthy repairman in my area. So I think that’s where it’s going to be until someone posts a series of detailed YouTube videos on disassembling and reassembling a machine (hint hint :).

No need to disassemble the machine, and in case you would need youtube for it, be sure you will not get it back together again.

Seizing up is usually caused by not oiling the sewing hook. Put one drop of oil every 20 hours in the front-bottom, and it should never seize up. This spot is also the ONLY point you need to oil on this machine. The bearings are sinter-bearings, who have a life-time oil inside (yes even +40 years. Don’t ever oil these, as the normal sewing-oil is too thin, and will not get into the bearings. An if it is the wrong oil, you can get even the whole machine glued up, or if it is too much at the wrong place, you can ruin the motor.

If this does not help, check for threads in the sewing hook area (especially at the back of the sewing hook) and remove them.

If this all doesn’t help, get a good repair-main that knows these machines, or download the repair-manual. (If you can understand German, there is also a good one online in the ‘Drachenwiki’)

I know the post are old but if you read this . I have fixed a few 1222 and 1222e models that were seized you have to use good penetrating oil like Deep Creep and let the machine sit. Take off the covers and spray everything but the motor. Mine mostly had the hook needed oil and linkage coming from the zig zag mechanism this is behind the main dial. I had to take out the automatic mechanism also the linkage was seized coming from the zig zag mechanisn and only way to acess was to remove it. Then I had to slowly move the linkage until it started moving and then I used my good synthetic Liberty oil for sewing machines and then I ran it without the automatic mechanism on, so no camstack gear then wipe any excess oil off and run it re wipe then re oil with sewing machine oil then run it. I even turned the machine upside down and sprayed the lubricating oil into the zig zag mechanism through the end were the belts are just keep oil off motor carefully wipe it off with paper towels or rags hook them to a wire if necessary be careful take your time. I have 2-machines right know and they both work great a 1222 and a 1222e and they both were getting tight.PS WD-40 is junk don’t use it use Deep Creep by Sea Foam just read the reviews.Do not force the machine one tiny piece of thread stuck in between the hook assy can jamb it

I have used a sewing tech at Seams So easy In Fairfield OH (near Cincinnati OH) His name is Michael. Maybe you could call him and see what he knows? You could ship it to him. He is a wizard on Pfaff’s and has a personal collection of them as well!

I have had my machine for many years and it has been good but yesterday the thread started going very loopy on the bottom and the top thread keeps breaking. Is there a pressure dial to tighten or loosing the bottom thread? In all these years I have never had this problem. I am in the middle of sewing the ribbon around the blanket.

Hope you can help me.

Thanks.

You can adjust the bobbin tension by tightening or loosening the tiny screw on the removable bobbin case (I do it with my thumb, no tool required). The manual gives instructions on how to adjust & determine when it’s the proper tension. Hope that helps.

I had this same problem on my 1222e. I learned that the device that holds the needle was worn out so it no longer held the needle in place. I think that is what caused my thread to loop because the needle was loose.

It is very frustrating

This is very frustrating.

I have a mint 1222. Great machine but I can no longer get service. Does anyone know how to set the timing? When the needle goes down it hits the bobbin and it breaks. I’m sure there are some alignment marks that I just haven’t found. If anyone can help me with a service manual I would really appreciate it. jeff and kathy

See:

http://www.quiltingboard.com/links-resources-f4/pfaff-how-repair-manual-instruction-manual-t153618.html

Try Brubakers in Pennsylvania. Just google the name & you’ll get a lot of info on them. & maybe call them.

Did you figure this out? I’ve been having the same problem with my 1222e, the needle hits the bobbin case when it goes down. Now in my case I had recently unscrewed things and cleaned all the dust out so I knew it was because I put something back wrong. I couldn’t find anything in the repair manual. After fiddling and then googling pictures trying to get a look at the bobbin area I believe that I simply needed to align the notch in the piece where the bobbin goes with the tab in the black piece that is under the feed dogs (not super technical terms, sorry I’m not a sewing machine repairperson). Every picture seems to have that notch at the top and it aligns perfectly, you can just see the tab in the notch in this picture (click to zoom)

https://i.ytimg.com/vi/67Qt7f3mXm0/maxresdefault.jpg

I hope someone else can confirm that this is how that works, I watched half a dozen youtube videos trying to see if I am correct and none of them mentioned it – perhaps its too rookie a question? I am new to this.

Download the repair manual as mentioned here above and go to chapter 36 (and/or 38.) 36 is a rather simple adjustment with taking loose 2 screws (in the black part on your picture, turn to the correct position and tighten these screws again.

Simultaneously, David Draganac, Pfaff Porsche s certified Porsche Classic technician, has been restoring the vehicle s mechanical parts.

Is it possible for you to share the User Manual? the pictures are much more clear then I can find online.

Hi,

Can anyone help me out on a good quality needle. I always bought Schmetz but they’re now doing out of the needle holder. My husband said there is definitely a difference in circumference. Thanks for any help Sally.

I was having a similar problem, which seemed to spread to almost any needle! I replaced the needle holder and it helped for a bit, but then started up again! I took the needle holder over to the hardware store and bought a slightly longer screw to fit into the needle holder and I haven’t lost a needle since! I believe it was a #8 metric screw, 1/2″ long. Good luck!

All of the older needles work perfectly

Do they also have the same shape? There are different shafts, of which some are smaller, but then the shape usually is also different.

Does the box say 130/705? If not then you got the wrong shaft.

re: falling out needles. I had this problem. My sewing machine repair guy said that the screw was slightly bent, and indeed, my needles have stayed in since he replaced it. However, I found a very interesting youtube video that explains that it is more likely a problem with the “needle clamp”. He did not mention the solution (replacement? are these available?). The needle clamp is mentioned starting at approximately the 6:30 mark. https://www.youtube.com/watch?v=bTkCAcCMb1Y

I replaced the whole needle clamp and haven’t had problems since, and of course it was easy as pie to do and the part only cost about $10-15 (but I don’t see a part number on it!).

Hi I’m looking for a zipper foot with needle hole on the left side of the foot AND a slot to engage the walking foot…have found plenty of these feet online but not compatible with the walking foot. Ie. no slot…i hate the zipper foot supplied with the machine (right side hole)

I know this only when you have the rare Pfaff holder.

I am late to the party here… but…. the manual does tell you that the zipper foot is to be used: The one that people seem to hate. It does not say “Engage dual feed”, which means that pfaff didn’t intend to use the IDT mechanism while inserting a zipper. There was no zipper foot with the IDT space at the time. With the use of the presser foot ankle attachment, which came along later (no longer available), it is possible to “snap on” a zipper foot with the IDT space.

You may use one of the “automatic” zipper feet… but cannot use the IDT (aka dual feed) at the same time. The last letter in IDT is Transport… meaning that it adds an additional/positional foot to move (transport) the fabric with the rest of the presser foot/feed dog transport. Sorry for the big delay, but i just discovered this site.

The white dot on the stitch selector knob keeps shifting to the right and is no longer at the 12 o’clock positions! How do I fix this?

Bring it to a (preferably older) Pfaff repair-man. The bearing is loose, and needs to be fixated with a pin. This is not an easy fix to do yourself, unless you know how to handle metal very well. Also if you disassemble too much it is almost impossible to get together again.

Hi y’all! I find this post to be very informative, thank you! I’m currently looking to buy a Pfaff 1222 or 1222E and I can’t decide which one. (I guess it really depends on which model I find on ebay or craigslist)

The ability to use industrial feet is a HUGE plus for me. Does anyone know if the 1222 can also take the same feet?

I am a professional seamstress and have been using a Bernina 830 Record (for travel) and my Juki DDL at home. I love them both but am sooooo curious about the IDT/built in walking foot.

Also if anyone has any tidbits on which they prefer 1222 or 1222E, I’d appreciate that as well. I don’t need to do embroidery, so the # of designs isn’t important to me, just which ever is the better, more reliable machine.

I guess my concern was if the extra stitches and electric foot pedal on the 1222E were just more things to potentially go wrong?

Bring it to a (preferably older) Pfaff repair-man. The bearing is loose, and needs to be fixated with a pin. This is not an easy fix to do yourself, unless you know how to handle metal very well. Also if you disassemble too much it is almost impossible to get together again.

BTW, the ability to use industrial feet is for all the executions exactly the same.

Bring it to a (preferably older) Pfaff repair-man. The bearing is loose, and needs to be fixated with a pin. This is not an easy fix to do yourself, unless you know how to handle metal very well. Also if you disassemble too much it is almost impossible to get together again.

placed wrong

This model had several iterations, which are not at all bound to the designation 1222 and 1222E or even de 1222SE (the last version).

All have electronics, the older ones SEL-electronics, the newer ones the Pfaff electronics. But this is not determined with the E or not in the type-name.

When you want to buy:

Get one with the Pfaff electronics. You can recognize this by the foot-pedal. You should not have the metal small pedal (beige color), but the plastic ones (white/black or complete black).

For the rest check on the camstack or the gears in the bottom don’t have a crack. The camstack is in the top, and is easy to see when you remove the topcover. Turn it around and you can check. The gears in the bottom you notice when you sew by irregularity every few turns. These cracks can be repaired by replacing the parts. The camstack is the most easy and most common, gears less common, and these gears can only be done by a good repair-man.

Last thing to check is if the straight stitch is really straight and doesn’t have a slight ZZ. Also this can be repaired, but this should be done by someone who knows what he does, and has the right tools.

In principal the newer models don’t have these problems. You can recognize this most easy by looking inside the top-cover. Here you can see a date-stamp (from ~68 till ~85). But which date is which change, is not known, and you never know if a repair already has been done by the previous owner.

BTW, the ability to use industrial feet is for all the executions exactly the same.

Thank you so much! Very helpful! I did wonder why different machines of same model # had different pedals! I wouldn’t never known that.

Hi .. you mentioned,check the straight stitch is straight and doesn’t have a slight ZZ, what does this mean, or what is the problem?

If it has this sligth ZZ when put on straigth stitch between 0-4 it means the bearing of the stitch-selector is loose and needs a repair. (btw between 4 and 5 on this dail, there should be a sligth ZZ)

We have a Pfaff 1222 – It has sit for about 5 years. My wife wants to start sewing again .. turned it on and the motor starts to hum .. then it ever so slowly starts to move and then jerks and starts again but never completely goes full revolutions .. hope you understand my description. I have the side off and both belts look good. As the motor starts to turn it looks like its sticking and I can see grease on the armature of the motor. Not sure if this is good or bad. I can turn the black wheel by hand and the machine will rotate through its positions but its very tight. Seems the motor is trying to move but struggles.

Can you give me any help on what I can/should do. I can send photos if needed. We live several hours from a large city and have no repair business in our community. Thanks you in advance, I’m Tim Hickman Southern Arizona

Put a drop of oil in the bottom front of the bobbin. No oil at any other point. (see also the manual)

Than check if it turns better.

The machine is self lubricating, but it needs regular running or heating up. You can put it on a heating, or use a hair-dryer. Than let it run for some time. It should start running faster. Off course only let the motor run if it turns freely and not too long in the beginning.

I need help with the needle position on my 1222e. The needle remains in the right side position despite moving the knob. Is there a simple fix? Thank you in advance.

Thank goodness I have a Pfaff 1222E which my husband bought me in 1959. I had a problem with the needles always breaking so I took it to a dealer and he made the hole in the plate larger but that allowed fabric to go down into the machine and the needles still broke so maybe the timing was off. I kept taking it back as I had never had needles break on my mother’s old Singer. Finally, the dealer gave me a brand new 1222E and I have never had a problem with needles breaking since then. The Pfaff 1222E must be used to keep it in running order as if left sitting unused for a long time it will seize up but once serviced it runs like new again. I made all kinds of clothes for my family on that machine. I do recall that over the years I had to have two major repairs, which at that time were not overly expensive One had something to do with the white cams inside the machine (not sure what they are called but they are large white discs. The other major strange thing was having to have a lot of a kind of woven nylon fibre woven tape removed from inside the machine. I remember there was a lot of it bit why it was there is a mystery to me. It must have been needed as I do’t think it wawas replaced. Perhaps it was disintegrating. At that time I had a good repairman who had been trained in the Pfaff factory in Germany and he was the one who did the two major repairs and I trusted him but I moved years ago and don’t know if he is still alive now.

Eventually about 25 years ago I wanted a machine that does embroidery so bought a Pfaff 7570 (the last Pfaff completely made in Germany) I loved that machine but the mother board went on it twice. The first time I was able to have it replaced but two years later the replacement died and by that time there were no longer any replacement mother boards for the 7570. I could have had the mother board repaired with soldering work done on it but felt that was not a good idea so bought a Pfaff 2170 with an embroidery unit which I really liked but it only lasted less than 10 years and then it quit. I sent it in for repair and was told it had become a boat anchor as the Power Control Board had died and there were no replacements. I am no longer young and have ended up using my original old Pfaff 1222E which I just had serviced. When I picked it up after it was serviced, I was advised to hang on to it as they don’t make machines like it any more. I miss the computerized 7570 and 2170 but am no longer confident in Pfaff machines so would not buy one again and do not trust any other brands either as all of them have their parts made in other countries and after 10 years they stop making parts for them.I feel I only need a machine for a few more years to do quilting and an occasional buttonhole and the 1222E will do that. I was able to buy an adapter shank for the 1222E that allows me to use all the fancy clip on feet from the 7570 and 2170. When the 1222E was new it outshone all other brands because it looked so modern and streamlined and it still does look like new.

Wow, I look forward to 60 years with my Pfaff! I was super lucky to snag this machine and it was worth every penny.

Very nice story, and exactly the reason I also have the 1222 SE, but the 1222E was only produced from around 1974/’75, so I assume you have it since 1979. This means still almost 40 years of pleasure to use such a beautiful machine 🙂

Hello

Please someone help me with my Pfaff 1222e. The feed dog is lowered and it’s not snapping back up. The fabric is not moving at all. Is there a way to pull it back ? Or is there any lever to pull it up ? Please help.

Hi, I just found this page as I searching for a part for my Pfaff 1222e. It is the black plastic piece on the backside, used to lower and raise the foot (don’t know what it’s called).

My sewing machine is used a lot and this piece has broken off, do you know what it’s called and where I can order one?

Thank you!

Foot lifter. Part# 93-040191-41 only available second hand, so try ebay. As it is usually only the plastic you could also make a new (plastic) piece with a hole a bit small and press it onto the metal shaft.

Hi I have a 1222e and sewing very happily until the handwheel jumped off. Not sure why but it seems as if the plastic handwheel screw came apart leavimg the screw in the machine while the plastic head separated. Any one dealt with this type of problem before? Bit of a double whammy. Need to get the screw out … no head and then replace the handwheel screw part. Love the 1222e

This is a known weakness. There are replacements available in both plastic and metal. Removing of the remaining screw-part is normally not very difficult by (keep)pressing the broken of head placed back in place with the screwdriver and than slowly turning. Some glue could help here.

I am new to this site and not sure how it works to post something. But here goes

I do have one thought about you folks whose machines have been jamming.

Whenever this happens to me , it is usually because there are threads behind the bobbin holder.

I have managed to pull out several feet of different threads from time to time.

It’s hard to see and reach them, but very satisfying to extract them!!!!!

You also must make certain that your message that you just

want to ship as an email doesn’t contain any express content.

Tip four – It will be significant that you also discover

out whether or not the SMS gateway service you want to use allows you easy accessibility to their supply

code scripts. In order that can assist you make a extra knowledgeable decision about which SMS Gateway to make use of we offer

some suggestions under chances are you’ll find helpful.

You might want to subscribe to the service with the intention to get

entry to full POP3 service. A soft bounce may additionally

happen if a recipient is away and they have set their mail to

send an out of office reply which means your mail will still get

learn upon their return. Email bounces are when you have sent mail out to electronic mail addresses which are now

not valid or exist, which signifies that your mail gets sent back with a failure discover.

It would most likely be helpful to maintain hold of most clients that

mushy bounce until you start to note a sample whereby the identical one or few addresses are delicate bouncing recurrently.

Such a bounce is often momentary and usually happens as a result

of mail server being down, the recipients mailbox being full or the message is

too massive.

Anyone know where I can get a power board for a Pfaff1222E? Mine went poof. Otherwise the machine was working fine.

Does anyone know where I can get a power board for a Pfaff 1222E? Mine went “pop”, literally. Otherwise the machine was working fine.

https://www.naehmaschinen-ersatzteile.com/Ersatzteile/Naehmaschinenersatzteile/Leiterplatten-Elektronik/Leiterplatten-Elektronik-fuer-Pfaff/Elektronik-PFAFF-1221-1222-1222E-im-Austausch.html?listtype=search&searchparam=1222

But most likely it is just the capacitor, which can be replaced by a handy electronic guy with 2 new ones. That would cost much less.

I am looking for the power board, or circuit board for the 1222 E. Thank you for the reply. The link seemed to be for a power switch. As it was in German I could be wrong. The circuit board is located underneath the machine, a cell-phone sized board with the circuitry and electronics. Used to be, there were folks who could build circuits boards.

This is the full board, with the protective box around it. It is however only available if you need a 220V Pfaff board and if you send in your broken one.

Drikusniet, (or anyone else) do you know where I can get a power board for a 1221, 120V? Will a power board for a 1222 or 1222E, or even a different model year 1221, work in a 1221?

Dear Alliee,

For 120V boards I don’t know where to get them, as I live in Europe with 220-240V. But usually, they can be repaired, especially the PFAFF electronic board. There is no difference between the 1221 and 1222 in this regard, so they can be exchanged. However, there are 2 types of electronic boards, the SEL and the PFAFF board. You can use both in your machine, however the foot pedal has different potmeters (150K Ohm vs 20K Ohm)

Especially with the machines without the E this can be both, in the machines with the E (1222E and 1221E) this is always the PFAFF electronic board with 20K Ohm foot pedal.

The stitch selector on my 1222E is stuck. I can easily change the needle position, but when I turn the outer ring the whole outer part turns including the ring with the white rectangle at the top. Does anyone know how to repair this?

You most likely have a wandering ZZ-bearing. This can be repaired by adding a fixing pin. However it is not an easy repair if you don’t have the proper tools (especially the bearing is a very hard material, which you have to drill a hole in, where the outer casing is of Aluminium. If not done properly, you will damage the machine.

If you understand German I could share some links in which this repair is being described.

BTW, a quick repair is sometimes to push the inner needle position selector backwards. But it will not last.

Hi

If you understand German I could share some links in which this repair is being described.

If you could share these links I would appreciate it.

Ron

Does anyone know why my Phaff 1221 (almost identical to the 1222) suddenly stopped working? No power going to it at all. Was in the middle of sewing and the light went out and power went off. Could it be the cord and or foot pedal? Tried other power outlets and it still doesn’t work.

I have a Pfaff 1222 for sale! In very very good working condition with original cover and foot pedal.

Bj, j’ai 1 Pfaff 1222E et j’ai 1 problème de point. J’ai fait du zig zag, et quand je remets le point droit, elle continue en zig zag. J’ai débranché la machine et attendu quelques minutes, mais elle continue en zigzag. Si vous aviez une solution ça m’arrangerait. Je vous remercie, Mireille (Sombreffe Belgique)

You could try to push in the middle part of the big knob. If that helps, you have the wandering ZZ-bearing. This needs a repair by a professional that has experience with this kind of machine.

Hi

I recently purchased a pfaff 1222e second. I never operated anything fancy before so I have zero experience in high end machines. There are couple of things, which are bothering me; firstly, its speed is quite slow, I mean really slow. And, secondly, it’s idt is quite wonky–it moves couple of inches then keep hammering on a single point and keep on doing it for few seconds, move forward and stitches few inches beautifully again start hammering at one point, sticht few inches more, hammer again.. Rinse and repeat. The distance between one point where it stops moving and starts puncturing at one place to the other point of no movement is same, let’s 2.5 inches approximately.

Does anyone have any idea why it does so.

I live in a 3rd world country and there is pfaff repairman around 5099 km around me.

I will highly appreciate any help.

Regards

Make sure the dual feed mechanism is fully engaged. Also: put in a new needle, make sure the tension upper/bobbin is the same… you have to pull on the thread from the needle and from the bobbin… you will be able to feel the difference.

Have you been using the proper feet? The IDT (dual feed) only works with presser feet that have a space in the back of the foot to accommodate the IDT action. Make sure that you take the presser foot, needle and needle plate off the machine and clean (with a brush of some kind) and tweezer out any thread that is stuck. Remove the bobbin case, do the same cleaning and put one drop of oil on the front/bottom of the shuttle (aka.sewing hook/raceway) Replace the bobbin/case in the right place.

There is a small possibility that the IDT mechanism is bad,,, not necessarily so.

Also, if you are not familiar with the presser foot bar in the back you need to use it and properly. If you turn your machine around to see it from the back the black bar (aka presser bar lifter) has 4 positions. Think of them as 10 o’clock A; 9 o’clock B; 8 o’clock C and 6:30 o’clock D. When you are actually using the sewing machine it will be facing you so the o’clock positions will change to 1, 3, 5, and almost 6.

Looking from the back of the machine:

Position A (10 o’clock) is the highest position and moves the needle and presser foot to their highest position. This allows you to not only thread your machine and needle, and add/remove material, but it must be there to wind a bobbin.

Position B (9 o’clock)is horizontal and raises the foot and allows you to move the material while the bar is horizontal.

Position C (8 o’clock lowers the presser foot into the ordinary sewing position.

Position D (6:30 o’clock)lifts the needle to its highest position without moving the presser foot up. This position allows you to “automatically” pull the bobbin thread up in a little loop in back of the needle; change the bobbin because it is empty or broken; You have to hold the bar in position D… when you release it it returns to position C.

You can download a user manual from pfaff.com for the 1222. It is free and very useful.

good luck and happy sewing.

If some one needs expert view regarding running a blog

after that i advise him/her to pay a visit this web site, Keep up

the nice job.

Excellent weblog here! Also your web site loads up fast! What host

are you using? Can I get your associate link for your host?

I desire my website loaded up as fast as yours lol

How you can Register for a Userbolavip Account

To be able to register as a member on the Userbolavip internet site, the method is usually very easy, the first step an individual have to carry out

is visit the official website or through the latest alternative link given by Userbolavip: Bukauserbolavip.

com

Via the alternate link above a person will go right to the principle page and the

upper right corner, click on the ‘REGISTER’ button to enter the registration web page.

Then you may find a page together with several fields that will must be filled in with your private data completely and

correctly.

After generating sure that almost all fields are stuffed in appropriately in addition to correctly, complete

typically the registration process simply by pressing the ‘REGISTER’

button which is at the bottom of the registration webpage.

Within a few minutes you will get confirmation that this

bank account you created is active.

Userbolavip Online game Login

After signing up, you will get a person ID and password which a

person can use in order to login the game. To do therefore, get

back to the primary webpage of the userbolavip internet site with the leading you will locate two

columns that the username plus password.

Enter your username and pass word in both fields and

press the sign in key close to them. When successful, you will certainly be able to be able

to access online gambling games provided by Userbolavip.

Sbobet is the biggest city in Asia that has been awarded several times for providing the best facilities and services.

Sbobet has also pocketed several legal betting licenses in several

states which make it legal to market online

betting. Sbomabos as a trusted official bola tangkas agent which was around since 2010 also follows

the criteria of its official service provider. Sbomabos is now an official sbobet login provider site that provides 24/7 service to all Indonesian online gambling people.

Sbomabos as a sbobet gambling agent that has received official permission from

PAGCOR and is centered in the Philippines so it is legal to

market products from our providers. We here offer transaction processing under 3 minutes from up-and-coming small

to large nominal.

How you can Login to the Sbobet Indonesia Internet site

Sbobet is an official website that always provides updated alternative backlinks so that members can easily access the sbobet website.

Now all sbobet logon information can contact customer service from the state sbomabos website.

Members who have completed registration at sbomabos can follow steps to sign in sbobet such as accessing

the sbowin. com site, entering the username and password provided by our

cs. The particular sbo system also prioritizes member

security after logging in, for the first time the fellow member will be asked to enter

a new password. Members can also change their own username on the official

sbo website.

Hello

YOU NEED QUALITY VISITORS FOR YOUR: madebyjulianne.com ?

WE PROVIDE HIGH-QUALITY VISITORS WITH:

– 100% safe for your site

– real visitors with unique IPs. No bots, proxies, or datacenters

– visitors from Search Engine (by keyword)

– visitors from Social Media Sites (referrals)

– visitors from any country you want (USA/UK/CA/EU_)

– very low bounce rate

– very long visit duration

– multiple pages visited

– tractable in google analytics

– custom URL tracking provided

– boost ranking in SERP, SEO, profit from CPM

CLAIM YOUR 24 HOURS FREE TEST HERE=> ventfara@mail.com

Thanks, Melisa Hamel

UserbolaVIP Alternative Link

Through online gambling online games, you can get income as

well as entertainment without having in order to leave

your convenience at home. Any of these sites which offers

the finest online gambling games in Indonesia is UserbolaVIP.

Through this web site, you can locate various types of interesting

and popular gambling online games like soccer gambling, online

slots, online casino, lottery, on-line poker, arcade video games and so about.

Unlike other gambling sites that you could find on the internet, UserbolaVIP gives an individual various conveniences in online gambling video games.

As a brand new member, you will be given a lot associated with convenience in enrolling, getting lucrative additional bonuses,

including an option UserbolaVIP link that you can entry and never have to experience difficulties being

blocked or perhaps having to use a new VPN.

Excellent web page. A lot of handy data below. I am sending it to a couple mates ans On top of that sharing in tasty. And clearly, thanks within your sweat!

An intriguing discussion is value remark. There_s without a doubt that that you ought to publish a lot more on this matter, it will not be a taboo subject but normally men and women don_t explore these topics. To the subsequent! Lots of thanks!!

http://moving68045.blogzag.com

Choosing the best and most trusted place to doing online gambling has become the main requirement if you

desire to be successful in this business.

It doesn’t thing what game you play, be it soccer gambling, lottery gambling, casino gambling, online

slots or even cockfighting. If you can’t pick a well-behaved gambling site, after that you will end in the

works in failure.

Therefore, it is entirely important for those of

you who are new to the online gambling industry to know what criteria a site must meet in view of that that it can be said to be the

best and most trusted online gambling site.

Are you a enthusiast of online slot gambling

games? This game has been approximately for hundreds of years but is

still one of the favorite games in Usernesia even in luxury gambling places as soon as Las Vegas or Macau, slot machines are always nimbly lined occurring waiting for fans to pull levers and win jackpots that attain billions

of rupiah. .

But, did you know if this game was initially considered a flop game?

Yes, at the initiation of this game created by its creator

named Charles August Fey in 1894 in the allied States, this robot was designed as an automatic poker game machine that could be moved using coins.

THE MOST EFFECTIVE AND RELIABLE BOLA TANGKAS JUDI BANDAR

Agen-338a is an online bookie that works officially with the sbobet provider.

Agen-338a has served wagering members from 2010 until now

and has never given frustration in phrases of sbobet login. Our company is also one of the sbobet brokers who have

received several awards and have now become the number one site in Philippines.

We have been also a site that is visited straight from the official sbobet

service provider to be entrusted with marketing

sports gambling products, internet casinos, slots, shooting species of fish, etc.

for the Indonesian community. Every day there are more than 10, 000

members who definitely play on our official site and provide reviews that

are extremely satisfied choosing us all as the companion agent.

Our brand searches also exceed 10, 000 lookups daily and

we are a 24/7 service site.

How to Register a Sbobet Account

We offer official sbobet bank account registration for all members who want to join without the fees

or requirements. We also what is simplicity in the sbobet list, because to complete

the sbobet account registration process, only affirmation is required that you are 18+ and have a

local lender to make purchases. Sign up for sbobet

can be through the registration form on the state website of Agen-338a or through our customer service who is willing to help you at any time.

After filling in the registration form, the member just must activate the ID with confirmation via

our cs.

I recently received a Pfaff 1222 e from a good friend, whose late wife inherited it from her grandmother. I do not sew, but took an introductory class at a sewing studio. The teacher looked over the machine, and tried to get it working but it would not run. I took the machine to a Pfaff repair shop, and was told it has a cracked cam stack, and would be very difficult/expensive to repair. I am interested in selling the machine for parts. Does anyone know how to go about doing this? Thank you.

It is not difficult to repair. And the cam can still be purchased (although not original)For parts or selling, you can get in contact with Brubaker Sewing Center if you are in North America.

Where are you located? And do you still have the 1221??

Hi…Yes, I still have the machine. It is a 1222, not 1222 e. I did reach out to Brubakers, as suggested, and they advised that the machine is not worth repairing. They suggested selling as is for parts. I listed on FB Marketplace, but there was no interest. I live in the Hartford Connecticut region.

It is worth fixing and not that hard . there’s a video on YouTube of a guy actually repairing it.the cam you do you have to have a service manual and must line up the cam once you put it back together with the automatic system it does have tricky linkage parts you do need patience.It take several attempts and several hours but you will have one of the best sewing machines made.